Model No.︰PM1550-XP

Brand Name︰Nufern

Country of Origin︰United States

Unit Price︰US $ 1 / Meter

Minimum Order︰10 Meter

Polarization Maintaining 1550 nm

Telecommunication Fibers

Nufern’s Polarization Maintaining Telco fibers are designed for today's most advanced networks. Optimized for use at

1550 nm, these fibers are used in all PM applications for data and telecom. Nufern has applied its unique manufacturing

facility and capabilities to this product area and has established leading optical, mechanical and geometrical tolerances.

The bend insensitive versions of our fibers offer lowest bend loss and extinction ratios at small bend diameters enabling

our customers to reduce package sizes. Available in either 250 or 400 micron coating diameters and prooftested to 200 kpsi,

Nufern's PM fibers will meet the demands of all current and future applications.

Typical Applications

• Pump and signal pigtails

• Lithium niobate modulators

• PMD compensators

• PM patchcords

• Polarization sensitive devices

Features & Benefits

• Tight specifications — Highly deterministic results, highest product yield

• High fatigue failure resistance — Longest service life

• Bend insensitive — Survives application in tight geometries (B version)

• All fiber proof tested to > 200 kpsi — Critical for ensuring long term reliability

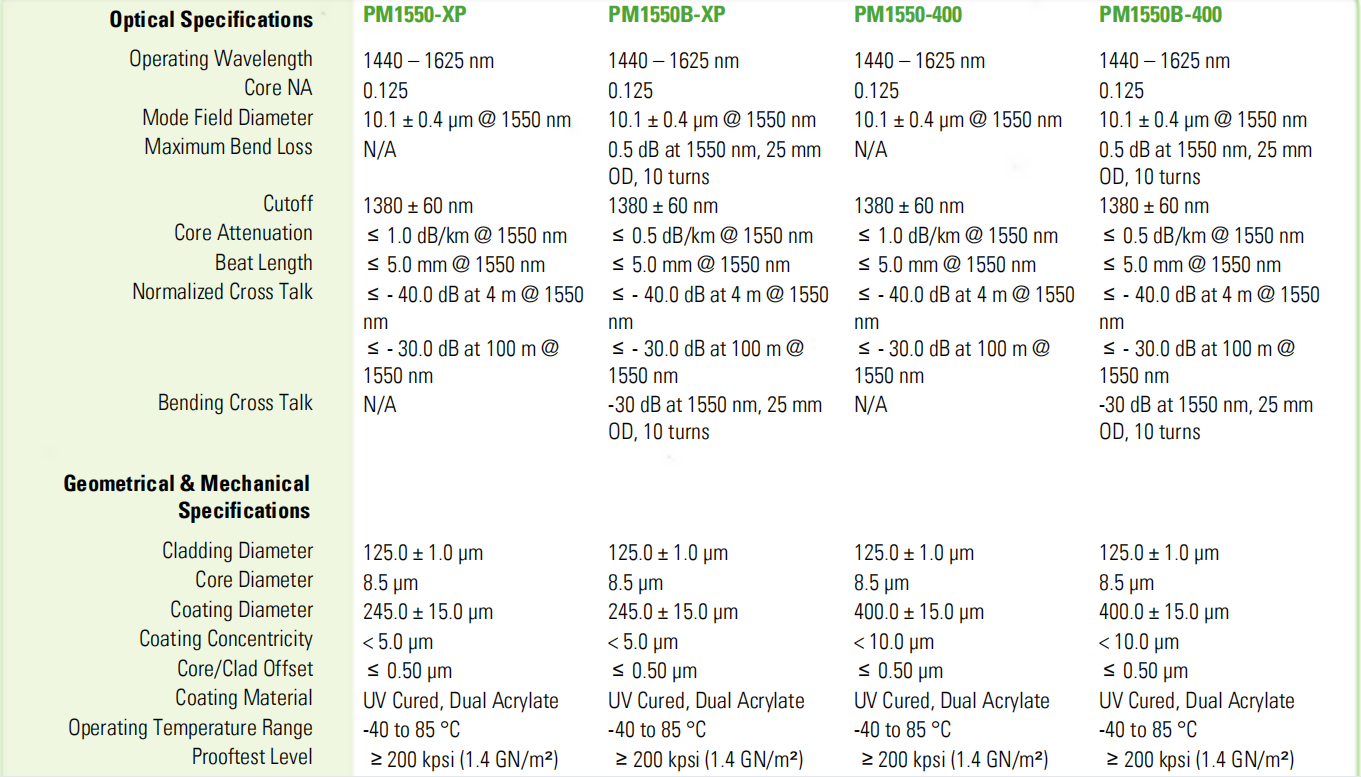

Optical Specifications

PM1550-XP

PM1550B-XP

PM1550-400

PM1550B-400

Operating Wavelength

1440 – 1625 nm

1440 – 1625 nm

1440 – 1625 nm

1440 – 1625 nm

Core NA

0.125

0.125

0.125

0.125

Mode Field Diameter

10.1 ± 0.4 µm @ 1550 nm

10.1 ± 0.4 µm @ 1550 nm

10.1 ± 0.4 µm @ 1550 nm

10.1 ± 0.4 µm @ 1550 nm

Maximum Bend Loss

N/A

0.5 dB at 1550 nm, 25 mm

OD, 10 turns

N/A

0.5 dB at 1550 nm, 25 mm

OD, 10 turns

Cutoff

1380 ± 60 nm

1380 ± 60 nm

1380 ± 60 nm

1380 ± 60 nm

Core Attenuation

≤ 1.0 dB/km @ 1550 nm

≤ 0.5 dB/km @ 1550 nm

≤ 1.0 dB/km @ 1550 nm

≤ 0.5 dB/km @ 1550 nm

Beat Length

≤ 5.0 mm @ 1550 nm

≤ 5.0 mm @ 1550 nm

≤ 5.0 mm @ 1550 nm

≤ 5.0 mm @ 1550 nm

Normalized Cross Talk

≤ - 40.0 dB at 4 m @ 1550

nm

≤ - 30.0 dB at 100 m @

1550 nm

≤ - 40.0 dB at 4 m @ 1550

nm

≤ - 30.0 dB at 100 m @

1550 nm

≤ - 40.0 dB at 4 m @ 1550

nm

≤ - 30.0 dB at 100 m @

1550 nm

≤ - 40.0 dB at 4 m @ 1550

nm

≤ - 30.0 dB at 100 m @

1550 nm

Bending Cross Talk

N/A

-30 dB at 1550 nm, 25 mm

OD, 10 turns

N/A

-30 dB at 1550 nm, 25 mm

OD, 10 turns

Geometrical & Mechanical

Specifications

Cladding Diameter

125.0 ± 1.0 µm

125.0 ± 1.0 µm

125.0 ± 1.0 µm

125.0 ± 1.0 µm

Core Diameter

8.5 µm

8.5 µm

8.5 µm

8.5 µm

Coating Diameter

245.0 ± 15.0 µm

245.0 ± 15.0 µm

400.0 ± 15.0 µm

400.0 ± 15.0 µm

Coating Concentricity

< 5.0 µm

< 5.0 µm

< 10.0 µm

< 10.0 µm

Core/Clad Offset

≤ 0.50 µm

≤ 0.50 µm

≤ 0.50 µm

≤ 0.50 µm

Coating Material

UV Cured, Dual Acrylate

UV Cured, Dual Acrylate

UV Cured, Dual Acrylate

UV Cured, Dual Acrylate

Operating Temperature Range

-40 to 85 °C

-40 to 85 °C

-40 to 85 °C

-40 to 85 °C

Prooftest Level

≥ 200 kpsi (1.4 GN/m²)

≥ 200 kpsi (1.4 GN/m²)

≥ 200 kpsi (1.4 GN/m²)

≥ 200 kpsi (1.4 GN/m²)

Payment Terms︰ TT